What is the cleaning scope of the photovoltaic panel cleaning robot

With the continuous investment of the state and relevant enterprises in the field of intelligent manufacturing, combined with various operation and maintenance difficulties of photovoltaic power plants, we have developed intelligent devices such as UAV detection, parts cleaning robots, and have applied the results to the photovoltaic operation and maintenance field. The advantages of intelligent robot are water free cleaning, intelligent control, unattended, free setting of operating parameters and convenient charging. For household products, the components can be cleaned basically without manual intervention. For large power plants, robots can save a lot of labor. Of course, the foreign body cleaning robot is still semi-automatic.

The types of photovoltaic panel cleaning robots are complex and diverse. In particular, the component layout of distributed power plants limits the installation scope of the robots to some extent, such as cleaning range and cleaning distance. If the actual scene is complex, you need to customize the robot equipment. The colored steel tile roof has a certain history. When the roof is updated a few years later, the robot equipment needs to consider the problem of secondary disassembly and assembly.

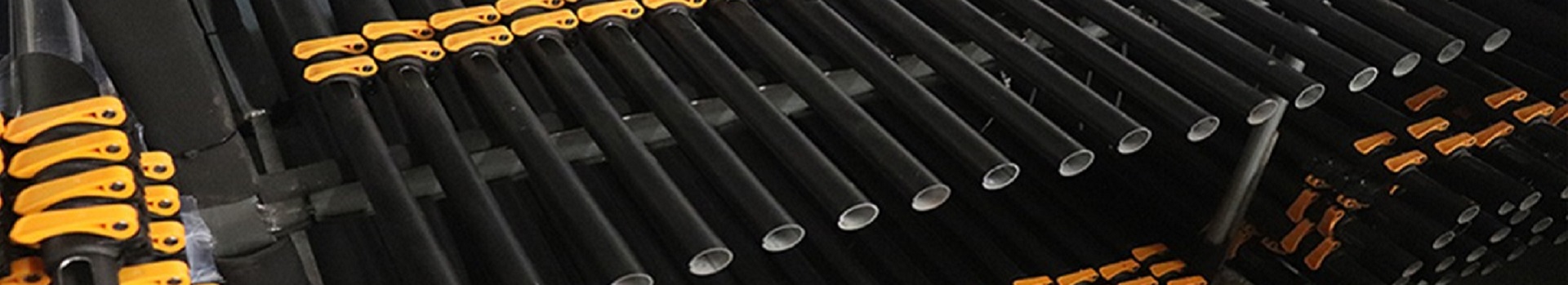

Depending on the type of power station, there are many cleaning methods for PV modules. For example, semi-automatic cleaning vehicles can usually be used to clean large ground power stations in the desert, as shown in Figure 1. This cleaning method is only applicable to power plants with relatively flat ground and large slope. The ground must be within the acceptable range, and the spacing of the square array must be large enough for the cleaning vehicle to pass through. It cannot be used on steep slopes or mountain power stations.

PV modules are usually installed outdoors to generate electricity. As the outdoor environment is not ideal, pollutants and dust in the air may fall on the glass surface of the module. When the dust accumulation reaches a certain level, the power and performance of the module will be affected. It has certain influence. Dust will not only reduce the effective radiation reaching the interior of the glass, but also affect the heat dissipation of the components. If the dirt is especially serious, it will also cause hot spot effect. For photovoltaic power stations near some chemical plants, dust with acid and alkali properties will also corrode the glass.

For the long-term reliability of equipment, the key components of ordinary robots are control motors, brushes and batteries. In the normal work life cycle, whether each component can be guaranteed also determines whether the investment and return of equipment can meet expectations.

For distributed power plants, due to their small size, manual cleaning is usually used. Due to the uniqueness of the distributed power stations on the roof, manual cleaning still has some risks. For example, cleaning dense square arrays is more difficult. People need to step on the frame, which can easily cause cracks in the components. In addition, it needs to be cleaned many times a year. Stepping on the colored steel tile roof also has the risk of water leakage, which is likely to cause conflicts between the roof owner and the photovoltaic power investors.

Latest News

Contact Us

Name: Daniel Chen

Tel: +86-18202237061

E-mail: [email protected]

WeChat: +86 18202237061

Whatsapp: +86 13702052069

Add: No.3, Yunnan Road, Heping District, Tianjin, China

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry